Aspen Construction Is Second to None

Aspen Power Catamarans are built to the highest standards by our experienced team led by our founder and president, Larry Graf, who is implementing his dream of building the ideal cruising boat. Many Aspen associates are boaters as well as builders, by using the boats our team gains understanding of what works well and where refinements can be made. While looking for the next amazing anchorage, cove, or remote waterfront village we find inspiration, and develop ideas that result in true innovation. We push the envelope when it comes to comfort, useability and efficiency in ways that don’t occur to other boatbuilders who build boats but aren’t really boaters. We build the boats tough because our family’s lives depend on them the same way yours do.

Not All Fiberglass Is the Same

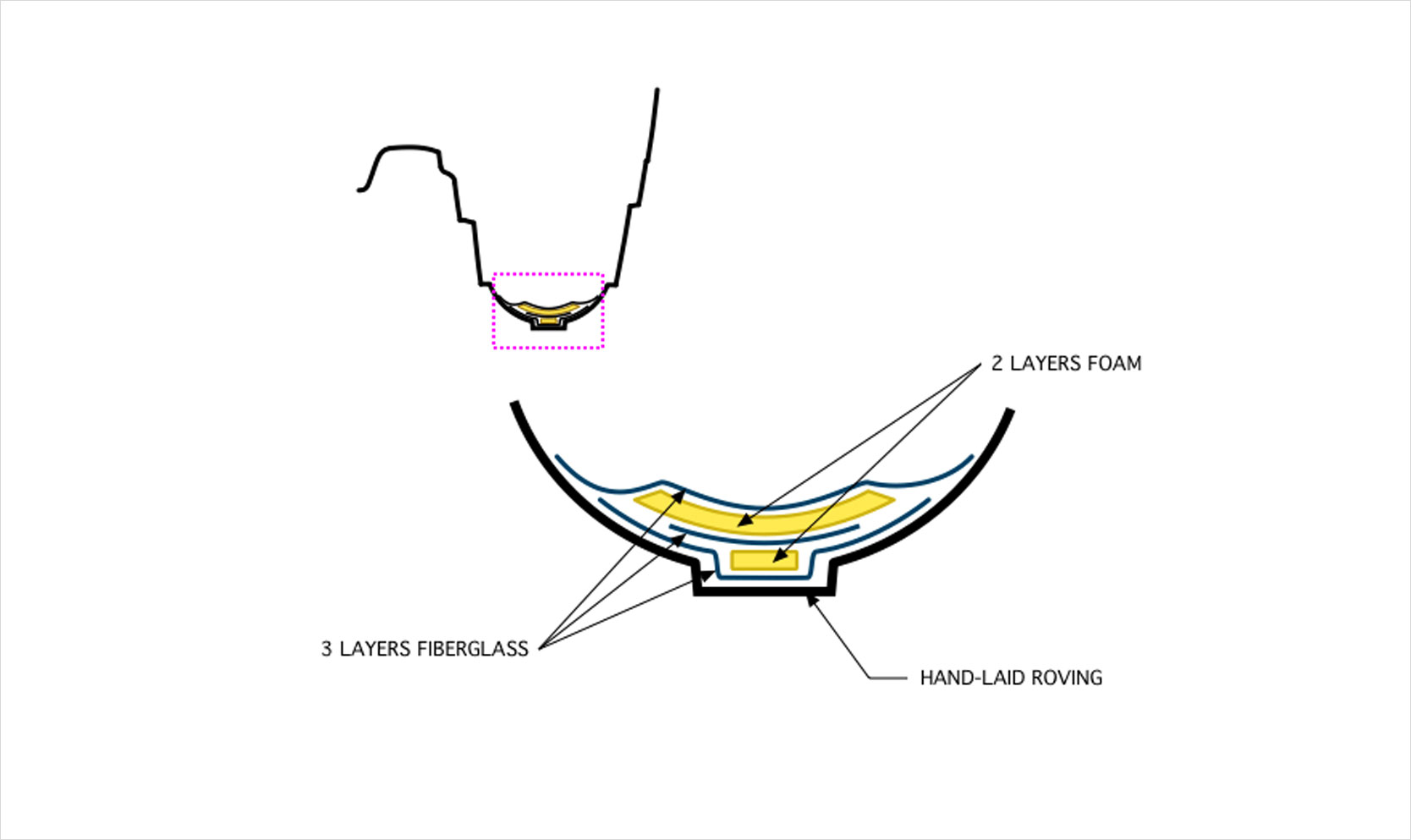

Fiberglass is a trusted material that has been in use for more than 45 years with excellent results but not all fiberglass boats are built the same way. Few builders have the construction knowledge and experience that Aspen has when it comes to building composite boats. The process used in the construction of an Aspen Power Cat combines modern technology with quality materials. Aspen uses premium Vinyl-ester and Isophthalic resins, S-glass, Kevlar, and cross-linked PVC cores ranging in thickness from a ¼ inch all the way up to 2½ inches. Construction is robust: Stringers and bulkheads are all made with synthetic Coosa board, a glass-fiber-reinforced urethane board and wrapped with up to a quarter-inch thickness of solid glass. The highest-quality UV-stabilized gelcoat is used, which is more expensive, but provides a better finish that holds both color and shine longer. These quality materials, combined with proper care in handling and advanced construction processes yield high-strength, lightweight hulls and decks that are very stable in the marine environment. Stability, quality, and durability are what ensures your boat’s strength and aesthetics into the future. Properly maintained Aspen hulls should last more than 100 years, which may exceed your personal expectations. This ensures your resale value, making your true cost of ownership among the lowest in the industry.

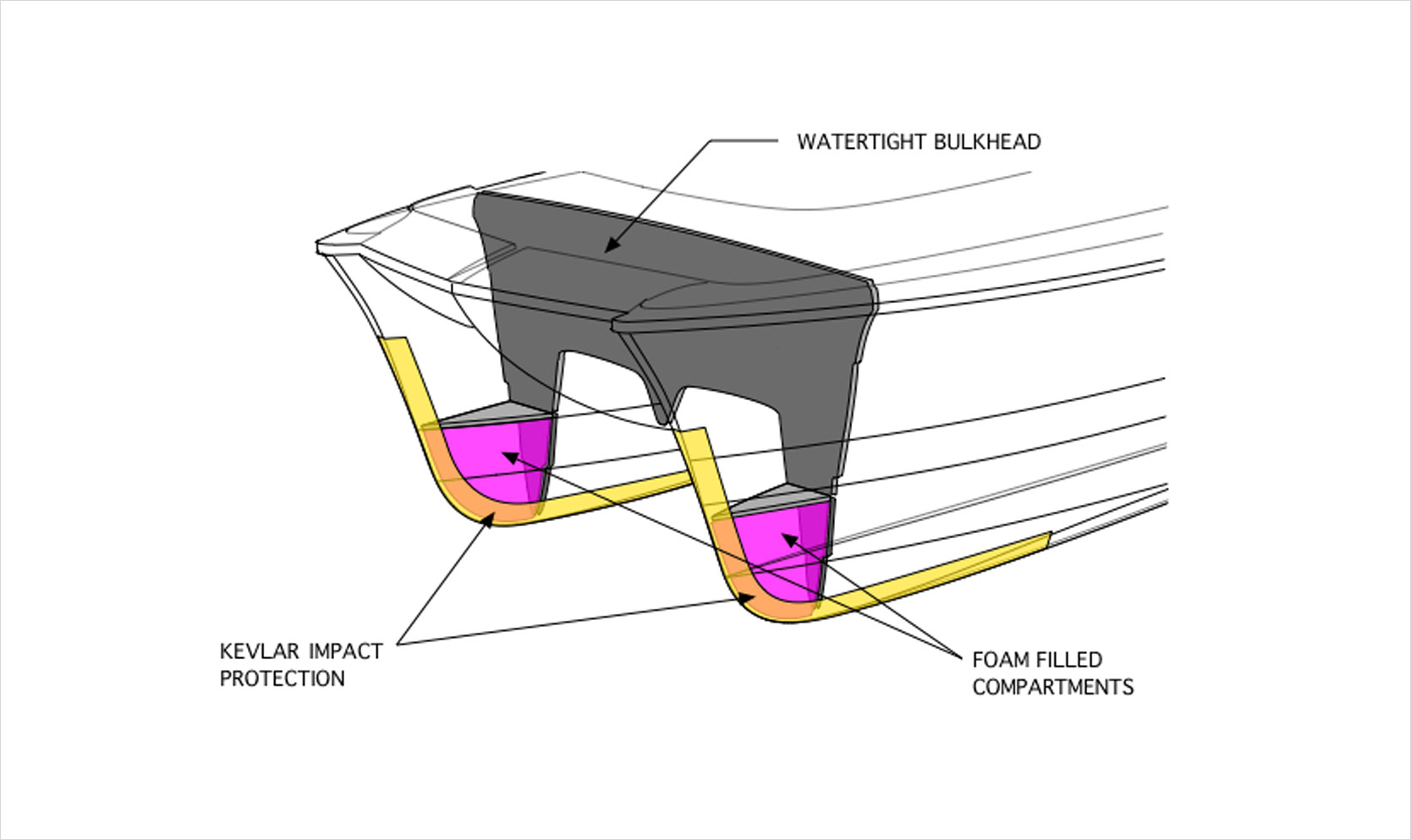

Aspen’s bows include an unusual degree of reinforcing behind the six alternating layers of mat and roving doubling over at the bow from each hull side, and we also add a layer of Kevlar. This material is exceptionally strong and will not fracture even on severe impact. In past boats with a similar construction, we have seen the result of actual high-speed collisions with immovable objects. We have found the Kevlar binds the core laminates in a way that makes them stack and work as one unit. This reduces or eliminates cracking upon impact even in extreme circumstances.

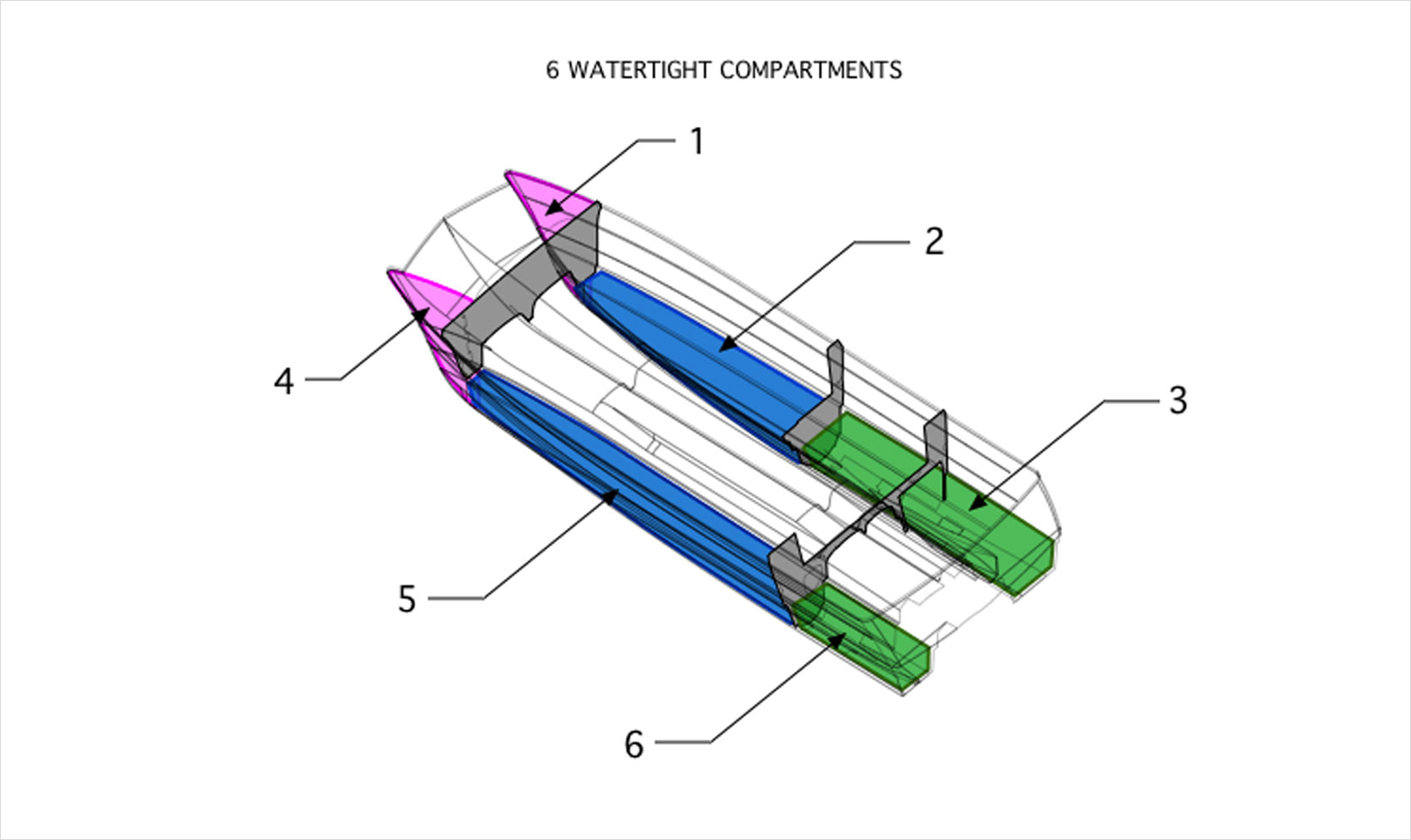

The bows of each hull have the first 3 feet boxed in with glass-wrapped Coosa composite board. These compartments are then filled with foam to 6 inches above the waterline. While a severe impact may damage this area, this construction will help keep the boat’s watertight integrity intact. While we don’t recommend using an Aspen as a battering ram, it is good to know that all Aspens are built with advanced construction that maximizes the safety of both boat and occupants.

If you have been boating long enough you know there are two types of boaters, those that admit they have run aground, and those that lie about it. Because Aspen owners tend to go on long trips exploring remote areas, we have included a double-bottom construction method. After the normal hull lamination procedure and thickness development, we go back in and add two layers of closed-cell cross-linked Divinycell foam; the first is a half-inch thick, the second three-quarters of an inch thick, and wrap each layer in glass and resin. When complete the hull bottom impact area is approximately 2 inches thick. In the bottom of each watertight compartment are bilge-pump wells, so the pumps placed in these 8-inch-square areas can completely evacuate the bilge, but 92 percent of the Aspen hull bottom is protected.

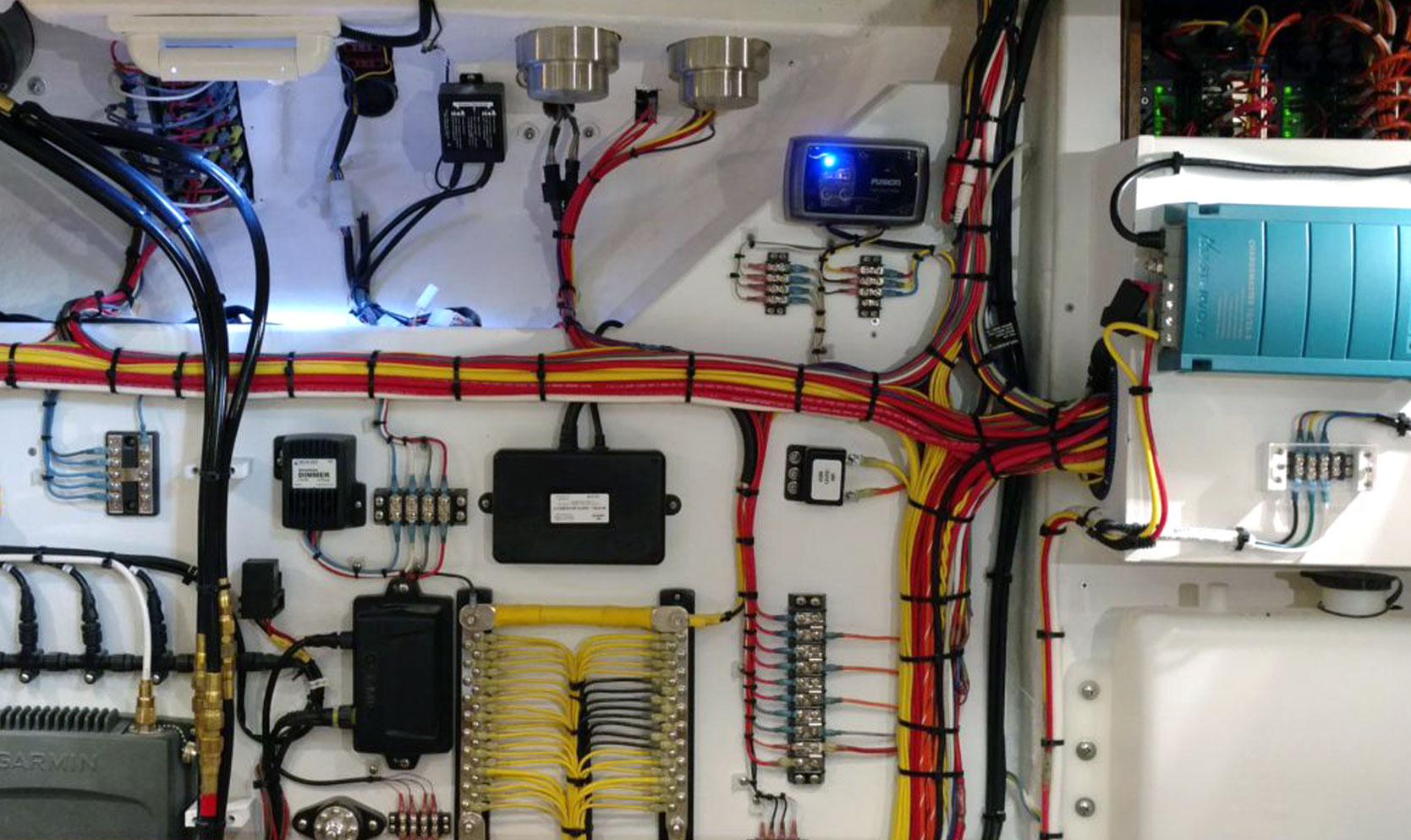

Electrical Systems Done Right

Well thought out, properly labeled, and precisely routed electrical systems prevent problems while also facilitating future repairs or additions to the onboard systems. At Aspen, all our boats start with a solidly engineered electrical backbone with tinned marine copper wire. Backing this up are yacht-grade 12-volt and 120-volt Blue Seas Systems panels, breakers, and hubs. Individual electrical components are chosen carefully from internationally recognized premium vendors that ensure their availability for future service. The installation follows ABYC standards for electrical systems and includes rigorous procedures and testing to ensure safe connectivity and flawless functionality.

Machinery and Engine Installation

Like us, our owners tend to be active boaters. We understand that our boats may be asked to perform in remote locations, traversing open oceans, and tend to be used more often and more consistently than other powerboats. We build each Aspen to last by ruggedizing them for many years of problem-free service. Engine mounts are 3/8-inch plate welded on both sides, exhaust systems are oversized piping with exceptionally quiet water-lift muffler systems, prop shafts are oversized diameter, and 5052 marine-grade U.S. aluminum fuel tanks are standard.

The Aspen Advantage Inside and Out

Aspen Power Catamarans are different than other recreational powerboats because we incorporate years of boatbuilding experience, practical on-the-water use, and innovative design to make a boat that is steps ahead of any other boat on the market. That is the Aspen Advantage. Larry Graf has been building powercats for more than 30 years. He started Glacier Bay Catamarans in 1987 and then founded Aspen Power Catamarans in 2008 when he developed our new revolutionary patented hull design (Power Proa) and drive system. Larry has been awarded more than 30 U.S. Patents over the years for his innovative designs and engineering. He and his team constantly work to improve every boat in order to produce and deliver boats of the highest quality achievable. Aspen is a family business with Larry’s wife, two sons and daughter all working to ensure that the program continues into the next generation and beyond, and won the 2018 Washington Family Business Award from Seattle Business magazine. In addition to the immediate family, Larry’s extended Aspen family consists of boatbuilders with over 100 years of combined experience. All Aspens are built in-house from start to finish in our state-of-the-art 30,000- square-foot factory in Burlington, Washington, USA. Our family business model goes beyond just having five family members working for Aspen—we treat our customers like family too. Because we sell our boats factory direct, you will be working directly with Larry, the rest of the Graf family and the Aspen team to ensure that your boat exceeds your expectations.